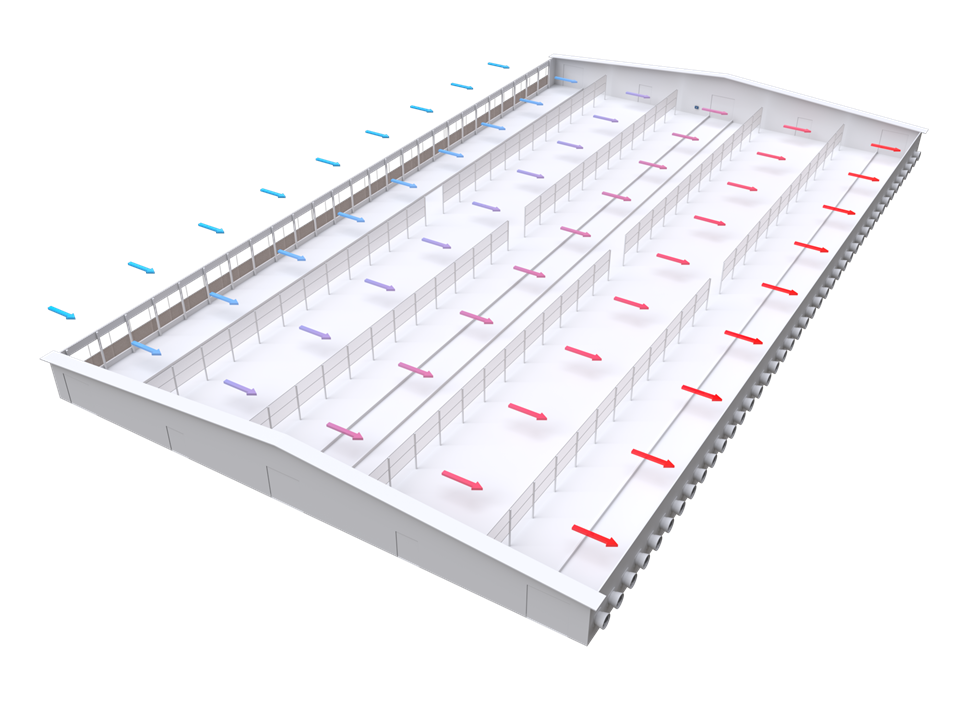

Cross-tunnel ventilation

The system is most suitable in regions with warm summers and mild winters. Tunnel ventilation is a negative pressure system suited for all types of livestock production, including dairy.

Cross-tunnel ventilation has recently become one of the most attractive and revolutionary concepts used in the dairy industry, especially to relieve heat stress during hot weather conditions. It is the best system to cool the cows using air velocity to maintain their productivity, and the barn can also be built wider. Cross-tunnel ventilation is the best Tunnel option in large-scale barns to ensure even climate conditions in the barns. Cross-tunnel systems have inlets along the entire length of the barn. This provides more evenly distributed air over a greater distance. The airflow in Cross-tunnel systems goes perpendicular to the feed lane, and the air travels parallel to the stalls, which is expected to give better airflow in the stalls. With the correct setups and operation, Cross-tunnel ventilation decreases the temperature in the barn while providing a constant stream of fresh air.

A baffle system can be installed to achieve a higher airspeed in the stalls without adding more ventilation capacity. Baffles installed above the stalls would increase the airspeed where the cows lie down.

For additional cooling in hot regions, a dedicated cooling system can be added to the ventilation system. We would recommend adding pad cooling or high-pressure cooling that reduces the incoming air temperature for better cooling, in combination with airspeed.

To make all the elements work in coherence and as they should be, a dedicated climate controller would be needed. In this way, it can operate all of the individual components in this system. In a situation where the temperature in the barn rises, the controller will not only turn on the wall fans but will also simultaneously start closing the sidewall curtains. This ensures that all air is coming through the tunnel-ventilation inlets. Our versatile BlueControl climate controller also works synchronically, adjusting the pad cooling to follow the targeted set temperature in the barn.

Benefits of applying SKOV-SECCO’s Cross-tunnel ventilation:

- Low initial costs

- Temperature stability within the livestock house

- Energy-efficient running cost

- Environmental stability will increase farmers’ profitability

- Cooling through air velocity

- No wastewater from the evaporative pad cooling

- Removal of excess heat and harmful gases

- Dry and comfortable bedding

- Efficient and easy climate control

- Healthy and productive cows

Equip your cross-tunnel ventilated barn with:

- BF 50 wall fan

- MegaFan PüRe tunnel ventilation

- Roll-up curtain

- Pad cooling

- BlueControl climate controller

➡️ Download the brochure here.

Making cross-tunnel ventilation work effectively requires careful design, precise measurement, and high-quality ventilation equipment. SKOV-SECCO International has over 20 years of experience in designing ventilation for livestock houses mainly dedicated to dairy, and we have installed many cross-ventilated barns in multiple countries.

Cross-tunnel ventilation system application in livestock houses